Extend the Life of Your Neuma Machine

So, you just bought yourself a Neuma tattoo machine and you love the way it tattoos, and you want to ensure that it continues to perform as well as possible for as long as possible. Understanding your tattoo machine’s inner workings, parts, and components plays a key role in maintaining its optimal performance.

The Importance of Tattoo Machine Maintenance

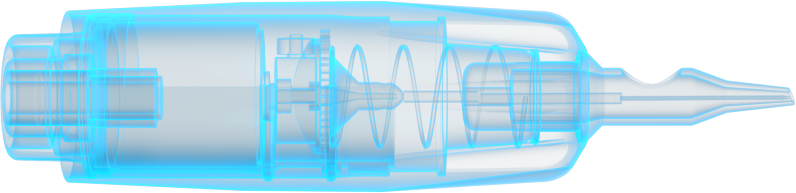

Maintaining your tattoo machine is essential for optimal performance. While avoiding physical damage like dropping your tattoo machine or exposing electrical components to autoclaving is important, the real focus should be on keeping the drive mechanism clean and well-maintained. One of the standout features of Neuma tattoo machines is their unique drive mechanism. Unlike most rotary tattoo machines, which use an angled or perpendicular drive shaft, Neuma tattoo machines utilize cams. These cams are a key factor in Neuma’s ability to enable tattooing techniques that other tattoo machines simply cannot achieve. However, they do require some routine maintenance to keep everything running smoothly.

Regular Oiling: A Key Maintenance Step

Regularly oiling the cam is the most important maintenance step for your Neuma tattoo machine. As a general rule, we recommend oiling every 50–100 hours of tattooing. Even if you consistently use the same cam without removing it, the oil will naturally break down over time through a process called lipid peroxidation, which reduces its viscosity and effectiveness. For this reason, it’s essential to remove and oil the cam after every 50–100 hours of use.

Cleaning the Transfer Case

While the cam is out, take a moment to clean the transfer case. Use a Q-tip to mop up any old oil from the bottom of the transfer case where the cam sits. To ensure a thorough cleaning, you may want to remove the bearing arm as well. This allows you to clean all the way down to the motor mount wall behind the bearing arm. When cleaning the bearing arm, use a Q-tip and a small amount of Madacide to sterilize the surfaces—avoid harsh cleaners like bleach.

Inspecting the Bearing

While you have the bearing arm out, inspect the bearing itself. Ensure it rolls smoothly without any grittiness, and check that the race (the outer metal ring of the bearing) isn’t loose or wobbly. For clarity, the bearing arm is the brass piece that attaches to the motor shaft in the center of the transfer case, while the bearing is the silver stainless steel part pressed onto a shaft on the side of the bearing arm.

Reattaching the Bearing Arm

After cleaning your tattoo machine, you can reattach the bearing arm using the set screw. The set screw should be tightened enough to maintain secure traction with the motor shaft but not over-tightened.

Preparing the Cam for Reinstallation

Before replacing the cam, apply 2–3 drops of the oil provided with your tattoo machine into the hole at the back of the cam where the motor shaft is inserted. This oil reduces friction between the spinning motor shaft and the cam, allowing the cam to slide smoothly up and down the motor shaft as intended, with minimal resistance.

Oiling When Swapping Cams

One of the most common issues we encounter is a lack of proper oiling, especially for tattoo artists who frequently swap cams. If you often switch between cams, it’s crucial to oil the cam being swapped in. For example, when you remove the 20% cam after finishing your lining and replace it with the 40% cam for soft gray and black shading, you should first apply 2–3 drops of oil into the hole on the back of the 40% cam where the motor shaft is inserted. This step ensures smooth operation by reducing friction in the cam. A lack of lubrication increases friction, which can overheat the motor, cause it to draw more current from the battery, and lead to your tattoo machine slowing down, getting hot, draining the battery quickly, and possibly damaging the motor.

Preventing Ink Overflow and Sterilization

It’s best to use cartridges with a membrane to minimize the risk of ink overflowing into your tattoo machine. However, if an overflow does occur or a membrane fails, the internal components of your Neuma tattoo machine can be sterilized. The bearing arm and bearing should not be autoclaved but can be soaked in a sterilizing solution like Madacide or Wavicide. The cam can also be soaked for sterilization. While cams can be autoclaved, we recommend cold or chemical sterilization to preserve their longevity.

Wear and Tear: When to Replace Components

Regular wear and tear is expected on any tattoo machine, especially one used daily or with many hours of operation. The bearing is one component that may fail or wear down over time. On average, you can expect 500–1,000 hours of use from a bearing. If the bearing does fail, replacements are available on our website at a minimal cost.

Cam Wear and Replacement

Cams are another component subject to wear over time, particularly due to the spinning motor shaft inside the cam’s center cavity, the contact point with the needle plunger, or the anti-rotation pin inside the transfer case. Neuma 5 FLEX cams typically last between 1,000 and 3,000 hours of use. If a cam breaks down, it can also be purchased individually from our website at a low cost.

Identifying Cam Wear

One of the first signs of cam wear is often the ramp at the bottom of the cam, where the bearing makes contact. While the cam may still function with some wear, replacing it when you notice roughness on the ramp can result in a noticeable improvement in performance. If you replace a worn cam, it’s also a good idea to inspect the bearing to ensure the roughness hasn’t caused it to fail.

Keeping Your Tattoo Machine Clean

As a general rule, keeping your tattoo machine clean and free of debris, grime, and dust will not only extend its lifespan but also keep it looking its best. A well-maintained tattoo machine reflects who we are as tattoo artists. When our tattoo machine is always clean and in good working condition, it demonstrates our respect for the craft of tattooing. Just like all of our equipment, our tattoo machine should be a point of pride and a testament to our professionalism and dedication.

Need Assistance? We’re Here to Help

If you have any additional questions, feel free to reach out. For warranty or repair concerns, we’re always happy to help ensure your tattoo machine operates at peak performance. You can refer to our troubleshooting guide [here] for tips, tricks, and detailed instructions. If you have a repair or warranty issue, you can complete the form [here].

For additional information about Critical Battery warranties and maintenance, please refer to this [here].